Ready-to-Use Cells in Bioassays for Quality Control of Biopharmaceuticals

C Jane Robinson, PhD

Scientific Liaison

Biopharmaceutical Emerging Best Practices Association

Email: [email protected]Jane Robinson is Scientific Liaison for the Biopharmaceutical Emerging Best Practices Association (CA, USA, www.bebpa.org) a non-profit organization for the presentation and discussion of scientific issues to facilitate safer and faster biopharmaceutical product development. She has a particular interest in the development of in vitro bioassays. Previously, she worked for 25 years at the National Institute for Biological Standardization and Control, UK, where she was responsible for the establishment of a laboratory for the standardization and control of polypeptide growth factors and related molecules of therapeutic and diagnostic potential.

Jane Lamerdin, PhD

Director, R&D

DiscoverX Corp

Email: [email protected]Jane Lamerdin, currently Director of R&D in the Enzyme Fragment Complementation division of DiscoverX (CA, USA), oversees the development of novel cell-based assays for discovery as well as bioassays for lot release and neutralizing antibody applications. Jane has over 16 years of experience developing cell-based assays to support drug discovery and systems biology research. Prior to joining DiscoverX, she was Executive Director of R&D at Odyssey Thera (CA, USA), where she played a key role in the implementation of a systems biology approach to characterize safety and selectivity of client molecules by utilizing a diverse high content cell-based assay panel.

Keywords

Ready-to-use cells, assay-ready cells, cell-based bioassay, potency assay, quality control

Introduction

A bioassay for potency measurement is a regulatory requirement for release testing for most biopharmaceuticals and is an essential tool throughout the drug development and production process. Cell-based assays are widely used for this purpose. Genetic modification of cell lines offers an increasing range of options for ligand specificity, measured cellular response and readout platforms. However, the common practice of maintaining cells in continuous culture, and harvesting some as required for use in an assay, presents a number of disadvantages. Similarly, primary cells, required for some assays, present challenges in their preparation. Many problems can be avoided if there is the possibility of taking a vial of ‘ready-to-use’ cells from a frozen bank of uniform, tested, aliquots and utilizing this directly in an assay.

Cell-based assays

For cell-based assays utilizing immortalized cell lines, historical practice has generally been to thaw a frozen aliquot of cells, then culture for a specified number of population doublings, or passages, to allow the cells to stabilize before they are used in an assay. Cells are then harvested, as required, from the continuous culture, up to a specified passage limit. This limit has to be set because most cells do not maintain their characteristics indefinitely in continuous culture and, beyond a validated passage number, their response in an assay may drift outside acceptable limits.

Such continuous culture requires considerable resources:

- Expensive consumables such as media and culture ware

- Labor time for cell culturing and record keeping

- Dedicated equipment such as incubators

- Laboratory space

- Infrastructure such as gas supplies, environmental monitoring systems, waste disposal

The delay between thawing the cells and their first use in an assay, and the need to plan expansion of the culture and timing of passaging to have cells ready for harvest, place constraints on assay scheduling. Cells from successive harvests have undergone a different number of cell divisions and have a different history of manipulation. The maintenance of the continuous culture increases the risk of variability and contamination of the stock.

Primary cells, i.e. cells that have undergone no, or few, population doublings since isolation from the source tissue, generally retain characteristics closer to their in vivo properties than do immortalized cell lines. This makes their use essential for some bioassays. However, variability in the source tissue and the isolation procedure contribute to variability in the assay results, and availability of the source tissue and length of the isolation procedure can constrain assay scheduling.

‘Ready-to-use’ cells

The disadvantages of maintaining cell stocks in continuous culture have driven the development of cell preparations that can be stored as a bank of uniform aliquots, ready for immediate use in a bioassay. These are variously described as:

- Ready-to-use

- Ready-to-assay

- Assay-ready

- Thaw-and-use

- Thaw-and-go

Initially, frozen ready-to-use cells were derived from the cells used in existing bioassays. Freezing and resuscitation protocols were optimized, and the performance of the ready-to-use cells was compared with those from continuous culture to determine whether they could be used as a replacement. Now, when developing a bioassay, it is commonly the aim from the outset to develop, if possible, a protocol using ready-to-use cells. The cells may be developed in-house or custom-made by a contract research organization. A further option is the increasing availability of off-the-shelf ready-to-use cells that offer a wide range of target receptors, intracellular signaling systems and readout platforms.

Development of cell banks

The development work required to create a bank of ready-to-use cells varies, depending particularly on whether it concerns a completely novel system or a modification of an existing system. As with any cells intended for use in assay systems, to permit the cells to be used in a GxP environment, preparation of the bank should follow relevant current guidelines and recommendations [1].

First, freezing media and conditions, and protocols for recovery of the cells, are investigated for acceptable consistency and performance of the cells. Then the bank is created, normally two-tiered, with a master cell bank and a working cell bank. As with any cell bank, vials are then selected for testing. This is likely to include appropriate sterility tests, post-thaw viability and functional performance, including the bioassay response. Even though the cells are intended for use immediately post-thawing, functional testing may include the growth characteristics of the cells.

A major advantage of utilizing a vial of cells directly from the bank is that there is less opportunity for variability to arise in the cells before their addition to the assay system than there would be in cells undergoing extensive manipulation and being cultured for different lengths of time. This reduces assay-to-assay variability and means that more of the quality control and system suitability testing can be performed on sample vials, and ahead of the assay, rather than on each cell harvest.

As consistency of the cells at the point of addition to the assay is a major advantage of ready-to-use cells, robustness of the protocol for thawing and for any preparation steps is crucial.

Ready-to-use primary cells

For potency testing of some biopharmaceuticals, it may not currently be possible to use an immortalized cell line and the bioassay will depend on the use of primary cells to assess a biological activity relevant to the clinical mode of action (MOA).

Human umbilical vein endothelial cells (HUVECs) can be prepared in-house from donor tissue or purchased cryopreserved. Under suitable culture conditions, they can retain many of their in vivo response characteristics, but only for a limited number of passages. Such ‘primary’ or ‘low-passage’ HUVECs offer a number of functional responses that can be used to assess the potency of biologicals with a MOA involving responses to vascular endothelial growth factor (VEGF) [2]. However, donor‑to‑donor variability and the change of characteristics over a short period of time in culture make these cells difficult to use for bioassays in a QC environment. Gazzano-Santoro et al [3] describe how these difficulties were overcome by expanding cells to a passage level that maximized yield while retaining endothelial characteristics, and generating a large bank of ready‑to‑use cryopreserved cells for an assay to measure the potency of a therapeutic anti-VEGF monoclonal antibody by AlamarBlue reduction. For each assay, a vial of cryopreserved cells is thawed and resuspended in assay medium, and then directly dispensed in the assay microplate. The authors note that it is critical to identify optimal growth and freezing media, cell passage number, freezing and thawing conditions, centrifugation speeds and cell density in vials, and that some cell types are particularly sensitive to thawing conditions.

Working cell banks of about 800 vials were created, and reproducibility of bank preparation by different facilities was demonstrated. Commercial vendors were then identified to generate large banks, with qualification performed by the originating laboratory. It was found that the use of ready‑to‑use cells significantly improved method transfer, avoiding the variability due to cell culturing which often proves a major challenge in method transfer between facilities.

Commercially available ready-to-use cells and assay kits

While some biopharmaceutical companies choose to develop banks of their own proprietary ready-to-use cells, there is also the possibility of purchasing commercially available ready-to-use cells in batch sizes and with supporting methodology, technology and certification as appropriate to the intended use. Commercially available ready-to-use kits for specific therapeutic targets are becoming increasingly prevalent and provide a solution to jump start method development for potency and characterization assays. These ready-to-use kits can provide all required reagents (ready-to use cells, plating reagents, control ligand and detailed standard operating procedures to allow easy implementation of the assay in a QC lab.

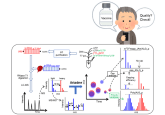

An example of such a system is the PathHunter® Bevacizumab assay (DiscoverX) which supports development of biosimilars to anti-VEGF therapeutics (e.g. Bevacizumab). The mechanism of action of these agents is to inhibit the growth of blood vessels in tumors by binding to specific VEGF isoforms, preventing activation of the primary VEGF receptor found on endothelial cells, VEGFR2. The PathHunter® Bevacizumab assay quantifies VEGF-A-induced homodimerization of the VEGFR2 receptor, which is the first step in the activation cascade of the receptor. This activation or dimerization event is blocked by the presence of anti-VEGF-A antibodies like Bevacizumab. Importantly, this highly robust method of testing Bevacizumab potency produces equivalent IC-50 values to the long-standing HUVEC proliferation assay with better precision and accuracy, and in a fourth of the time required to run the legacy assay [4].

The ready-to-use cells are manufactured to defined specifications for low intra-lot and inter-lot variation, and are shipped with a Certificate of Analysis. All reagents in each kit have been optimized to work together to achieve optimal performance in the assay, and the optimized protocols have been qualified to demonstrate repeatability, precision, accuracy and linearity utilizing a relevant therapeutic agent for the drug target.

As therapeutics for ever more difficult drug targets move towards the clinic, the potency assays to support them are also becoming increasingly more complex. For certain immuno-oncology targets, such as the immune checkpoint inhibitor PD-1, the use of co-culture assays to reflect the complex physiology of the target are required. For such targets, the use of frozen ready-to-use cells are even more important to minimize the variation that would be inherent in utilizing two different cell types in one assay. Examples of such assays are the PD-1 bioassays produced by Promega and DiscoverX, that use one cell type to express the PD-1 receptor (e.g. Jurkat cells) and quantify receptor engagement (or blocking with a therapeutic agent), and a second cell type to express ligand and/ or stimulate activation of the assay. Both bioassays are robust, precise and accurate, suitable for use in a QC environment.

Ready-to-use cells represent one of the major recent advances in bioassays for potency and characterization of biopharmaceuticals. The bioassay has traditionally been viewed as one of the most problematic of the analytical techniques required for QC and batch release. Frozen ready-to-use cells offer improvements in use of laboratory resources, assay scheduling, robustness and assay variability. Moreover, the increasing availability and variety of ready-to-use kits will allow more extensive investigative studies of biopharmaceuticals by avoiding the lengthy and costly development required for establishing a cell-based assay in a laboratory.

References

- Menendez AT, Ritter NM, Goyal J, Jani D, Zmuda J. Recommendations for cell banks used in GXP assays: preparation, characterization, and storage. Bioprocess Int. 10(1), 26–40 (2012).

- Burns CJ, Silva MM, Gray E, Robinson CJ. Quantitative RT-PCR as an alternative to late-stage bioassays for vascular endothelial growth factor. J Pharm Biomed Anal. 47(3), 460–468 (2008).

- Gazzano-Santoro H, Chan LG, Ballard MS, Young JC. Ready-to-use cryopreserved primary cells a novel solution for QC lot release potency assays. Bioprocess Int. 2(2), 28–39 (2014).

- Lamerdin J, Daino-Laizure H, Saharia A, Charter NW. Accelerating biologic and biosimilar drug development: ready-to-use, cell-based assays for potency and lot release testing. Bioprocess Int. 14(1), 36–44 (2016).