Interview with Erin Chambers (Waters Corporation) on the ionKey/MS system

Erin Chambers is a Principal Scientist, providing pharmaceutical applications development and support for Technology Advancement group. Erin’s primary role is to support regulated and discovery Bioanalysis, and develop bioanalytical methods for drug molecules, both large and small. She is responsible for sample preparation, mass spectrometry and LC method development, and also provides customer and in-house training on these topics. Her most recent focus has been on peptide and protein bioanalysis.

Erin Chambers is a Principal Scientist, providing pharmaceutical applications development and support for Technology Advancement group. Erin’s primary role is to support regulated and discovery Bioanalysis, and develop bioanalytical methods for drug molecules, both large and small. She is responsible for sample preparation, mass spectrometry and LC method development, and also provides customer and in-house training on these topics. Her most recent focus has been on peptide and protein bioanalysis.

Tell us a little about your role at Waters Corporation and your work on the ionKey/MS.

I am a Principal Scientist focusing on bioanalytical applications for large and small molecules, either therapeutic or endogenous. In addition to developing difficult applications, my group and I teach hands-on training courses, work with R&D to develop and test new products, and work with customers in several ways – from troubleshooting methods to collaborations. Some of the more interesting work we’ve done and continue to be involved in is in the area of diabetes and Alzheimer’s research.

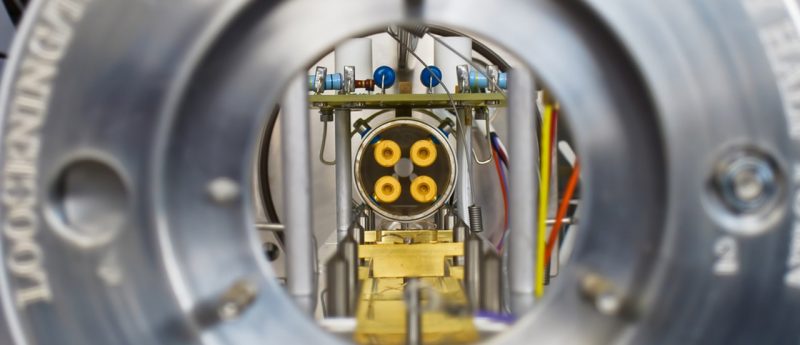

I’ve been in bioanalysis for about 20 years now, so I’ve seen a lot of changes and advancements. About a year and a half ago, we were lucky enough to get an ionKey/MS system in our lab. I was quite skeptical at first. Having used nano-flow previously as a proteomics demo chemist, I had certain preconceived notions. Quite frankly, it blew me away how easy it was to use. The first thing I remarked on is that the ‘column’ is essentially a single integrated device; you don’t even have to make any connections like you do at analytical scale. There are no worries about inadvertently introducing extra volume because the connection wasn’t made correctly, no worries about leaks, and no worries about cutting fused silica tubing. So, you don’t have to worry about the typical nano-scale issues. Furthermore, leaks and improper column seating occur at analytical scale, so you might even say that the ionKey is easier than both nano and traditional analytical scale. The next thing that surprised me was that even though we were working at microscale, it didn’t feel any different than the routine analytical work we do at 2.1 mm scale. Since we got the system in our lab, we’ve been running almost all of our peptide quantification methods on it – we’ve run everything from small cyclic peptides to intact insulins.

Can you tell us a little about what led to the development of the ionKey/MS system?

The initial driver was sensitivity – sensitivity for sensitivity’s sake of course, but also sensitivity from small sample volumes, specifically. The ideal application to run on an ionKey/MS system is one where the highest sensitivity is required and sample volume is limited. For small cyclic peptides, for example, we are looking at single pg/ml quantification limits from as little as 25 µl of sample. I think most people recognize that one can realize some significant sensitivity increases from going to micro or even nano-scale chromatography. The problem in the past though has been the robustness, reliability and reproducibility of these systems, as well as ease of use. So we needed to create a system that not only provided some real sensitivity improvements, but that also fit into a routine laboratory setting, and had the ruggedness and ease of use to withstand the rigors of a highly productive BA lab.

Can you describe some of the main benefits to using the ionKey/MS system?

I’ve sort of alluded to a few of these, certainly improving sensitivity is one of them, but it is important to realize that specifically we are talking about better sensitivity especially from smaller sample volumes. For example, one could expect to reduce the amount of sample required, reduce injection volume, and STILL see a significant sensitivity gain. This is really the crux of why we are talking about this technology relative to microsampling, it is an ideal pairing!

There are other benefits like reduced solvent consumption – ionKey/MS will use 50–60X less solvent than a comparable 2.1 mm method.

What are the implications of lower sample volume requirements within a laboratory?

Because less sample is used, it allows for more tests per sample, extension into pediatric patients, or the use of a single animal PK model versus a composite profile, resulting in animal and money savings (I’m talking about mouse/rat studies here).

Does the ionKey/MS system have any effect on the use of animals in the lab?

Absolutely, as I mentioned, one can significantly reduce the number of mice or rats used and simplify PK profiling. I think obtaining the whole profile from a single animal has got to be more accurate than the composite profiles or pooled samples that are often used.

In addition, minimizing animal usage is especially attractive when very specific, costly animal models are required for studies. When fewer animals are required and more information is gathered for each sample, studies receive more favorable reviews from internal review boards.

Have you encountered any challenges when transferring existing methods to the ionKey/MS?

It is certainly a little different than the direct scaling that one does from analytical to prep scale. In general, I find that we are shallowing gradients relative to the 2.1 mm methods we are transferring from. The other thing that is important to appreciate is the relationship between injection volume and chromatographic scale. We’ve shown 20–30X improvements or more, when injecting the same amount on analytical scale and ionKey/MS. It is quite common to inject 5–10 µl of sample at analytical scale (2.1 mm ID for example), and naturally one would hope to inject the same at microscale. This is possible of course, and it is interesting to put some perspective around what we are asking the system to do. A 5–10 µl injection on the microscale system, if scaled back up to analytical scale, would be the equivalent of injecting 1–2 ml of sample on a 2.1 mm ID column! That means that you need to pay attention to the injection solvent and your sample clean-up. It is no different than doing a large-volume injection at analytical scale. One of the ways we simplify dealing with this is through a trap valve manager, which allows us to load these relatively large volumes, focus the analyte band, and realize the sensitivity gains we are looking for. It really helps eliminate solvent effects and helps with loadability.

Are there any other new technologies or developments within microsampling that you are excited about at the moment?

Some of these newer blood collection devices in development have the potential to really change blood sampling and make it much more consumer friendly. There are those that adhere to the skin and collect more blood than a finger stick but less than a traditional needle that I think are pretty attractive. Innovations like those, that really improve the experience for the patient and can be done just about anywhere, are certainly something to look out for. These types of advances in blood collection also force advances in the accompanying technology. You start to see why the industry is so interested in microscale for the future.

Where do you see the future of microsampling?

I certainly see this area as growing. There are just so many benefits to working with smaller samples – whether by choice or necessity. I can only see its (microsampling) usage increasing. I think this is especially true as enabling consumables and instrumentation continue to evolve at the same time. We are now able to measure things we never could before, it’s really amazing when you think about it. Microsampling is going to be present everywhere, from biomarker discovery and validation to drug discovery studies, and through development and clinical. I am excited to be able to be in the scientific field right now. Every day there are new challenges and, fortunately, new technologies being developed to help meet those challenges.