What is lab-on-a-chip technology?

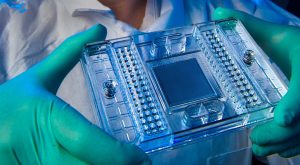

The ultimate aim of lab-on-a-chip technology (LOC) is to integrate one or more laboratory processes or techniques onto a single miniaturized chip. Theoretically, LOC technology has the potential to carry out almost any laboratory procedure on a miniaturized scale. This could range from DNA sequencing and biochemical detection to chemical synthesis, clinical diagnostics and biomarker validation.

What are the advantages of lab-on-a-chip technology?

Lab-on-a-chip technology offers a wide array of possible advantages over traditional benchtop operations. For example, a portable handheld device capable of performing point-of-care clinical diagnostics could find use in medical offices or remote locations where access to laboratory facilities and complex equipment is limited.

The miniaturization of traditional benchtop operations also has advantages for cost efficiency and the environment as a result of reduced reagent use and reduced chemical waste. Additionally, the use of low volume samples could reduce the burden on patients, by requiring smaller samples of blood/urine/saliva etc. Compared to conventional techniques, the use of LOC technology could increase operational efficiency. In theory, high parallelization can be achieved through the integration of microchannels, allowing many analyses to take place simultaneously on a single chip.

Such miniaturized devices also offer potential advantages through increased ergonomics, diagnostic speed and sensitivity.

Click here to check out five recently developed microfluidic devices!

What are the disadvantages of lab-on-a-chip technology?

Unfortunately, LOC technology is not without its disadvantages. Physical effects such as surface roughness and capillary forces become much more significant at the micro- and nanoscale. These pronounced effects can result in complications that would not be expected in traditional benchtop processes. In some applications, complications like poor signal-to-noise ratio can occur. As a result, in some cases, LOC devices could provide poorer results than conventional techniques.

To date, the main roadblock to the widespread use and development of LOC devices has been the successful design and fabrication of functional, cost-effective systems. Although the field is witnessing an ever increasing number of exciting proof-of-concept devices, the majority of LOC technologies are not yet ready for industrialization and commercial use.

What is microfluidics?

The development of LOC technology is closely related to developments in the field of microfluidics. The discipline of microfluidics is concerned with the behavior, precise control and manipulation of fluids that are geometrically constrained to a small scale.

In the case of LOC technology, microfluidics relates to the study of the behavior of fluids through micro-channels and the manufacturing of miniaturized devices containing chambers and tunnels through which liquids flow.

As well as microfluidics, LOC technology is highly dependent upon developments in the field of nanotechnology. Recent developments in stereolithography – an additive process that prints 3D objects – have allowed the fabrication of micro-scale valves, pumps and components used to manipulate the flow of liquids on LOC devices. As research continues, the ability to accurately create complex 3D architectures will become a widespread reality.

Click here to read an interview with lab-on-a-chip expert, Aaron Wheeler >

What does the future hold for lab-on-a-chip devices?

In 1991, Andres Manz et al. asked whether miniaturization of chemical analysis systems was ‘a look into next century’s technology or just a fashionable craze?’ Almost 30 years on it is clear that LOC technology is a very exciting field of research with a bright future ahead. It is, however, also clear that scientists must continue their sustained and collaborative research effort to continue to realize the advantages of this technology.

Click here to check out five recently developed microfluidic devices!

Ching T, Toh Y, Hashimoto M. Fabrication of complex 3D fluidic networks via modularized stereolithography. Adv. Eng. Mater. doi:10.1002/adem.201901109 (2019)(Epub ahead of print)

Daw R, Finkelstein J. Lab on a chip. Nature, 442(7101), 367 (2006)

Whitesides GM, The origins and the future of microfluidics. Nature, 442(7101), 368–373 (2006)

Manz, A, Harrison DJ, Verpoorte EMJ et al. Miniaturization of chemical analysis systems – a look into next century’s technology or just a fashionable craze? Chimia, 45(4), 103–105 (1991).